R4023Self-Propelled Sprayer

- Premium or standard cab for total comfort

- All-new sound suppression enhancements

- Compact size perfect for smaller fields

- New efficient 4.5L Tier IV engine

R4023 Sprayer

R4023 Sprayer

R4023 spraying in the field

R4023 spraying in the field

Built with the same kind of innovative thinking as its popular 4 Series siblings, the R4023 Self-Propelled Sprayer combines versatility, productivity, and affordability in a 2271-L (600-gal.) sprayer.

The option of either a wide or narrow axle configuration enables this sprayer to fit a wide range of row spacing needs. Additionally, the R4023 offers key features that provide for a smooth ride that is necessary for those long days in the field.

Equipped with up to a 27.4-m (90-ft) fold feature, the R4023 allows the operator to fold the boom in quickly for headland turns. With the ability to add precision ag productivity boosting features, the R4023 enables more accurate, efficient, and comfortable spraying applications.

Interchangeable inner booms

Interchangeable inner booms

3D boom structure

3D boom structure

The R4023 Sprayer's booms are built with high-strength square tube.

The boom incorporates a strong 3D design. This design gives the boom more strength to resist fore-aft loading generated by starts, stops, and turns, as well as twisting loads caused by folding and unfolding operations.

The boom plumbing and nozzles are set between and up inside the two bottom square tubes of the boom structure. This protects the nozzle bodies from hitting objects that could damage the sprayer or affect the spray pattern.

The R4023 boom comes in an 18.3-m/24.4-m (60-ft/80-ft) or 18.3-m/27.4-m (60-ft/90-ft) configuration. Simply fold in the outer wing and go from spraying at 24.4 m/27.4 m to 18.3 m (80 ft/90 ft to 60 ft). When the outer wing is folded over top, it is supported by cradles to ensure it remains in place and secure while spraying in the 18.3-m (60-ft) configuration in rough fields.

Increased boom sections provide the operator more precise application:

The breakaway ends of the boom offer the operator protection against damaging the boom if the boom unexpectedly hits an obstacle. The breakaway section of the boom uses a design that holds the breakaway from breaking backward while operating normally in the field, but when something is contacted, it moves rearward and out of the way to prevent major damage.

Each breakaway section resets using a spring, and then resets back to the spray position.

When the booms are folded in, the transport cradles on the machine support a large portion of the boom that, in turn, spreads out the stress.

While in transport position, the booms are cradled so that visibility is maximized to either side of the sprayer. By folding the booms flat, visibility is increased and overall height of the machine is not affected.

4.5L (274.6-cu in.) John Deere PowerTech PSS diesel engine

4.5L (274.6-cu in.) John Deere PowerTech PSS diesel engine

The R4023 Sprayer provides 129 kW (173 hp) with a 5 percent power bulge to 136 kW (182 hp) and 6071 kg/cu m (538 lb-ft) of peak torque to get through tough field conditions.

John Deere PowerTech PSS (two-valve) 4.5L (274.6-cu in.) engine features include:

In addition to reducing emissions and lowering engine idle noise, its compact size allows it to fit neatly under the hood for great visibility of the rows passing underneath the operator.

An increase in fuel tank size makes it possible to spray for up to 16 hours without refueling. By equipping the R4023 Sprayer with a 310-L (82-gal.) fuel tank, the operator will have plenty of fuel to spray for a full day.

The R4023 offers two factory installed shock solutions to accommodate various field conditions. For optimal comfort in rough or uneven terrain conditions such as no-till or stripped fields, select the Soft Shock option.

The Soft Shock takes the place of the adjustable shock dampener used on the 4630 and is offered as a factory-installed option. This fixed shock provides 50 percent less dampening force which allows for a smooth ride up to 32.2-km/h (20-mph) spray speed in uneven field conditions. The Soft Shock may also provide a more responsive feel for operators in turns or when starting/stopping quickly.

NOTE: The standard shock option is unchanged from previous models and is recommended for general use.

Cast mount for connecting rods

Cast mount for connecting rods

The suspension design on the R4023 Sprayer uses a four-bar link system along with an air bag and shock combination to provide a comfortable ride.

Two large air springs sit atop each axle, similar to those used on over-the-road trucks and other John Deere sprayers. These air springs are dampened with oil-filled shocks to smooth the ride.

Connecting rods link the axle to the large cast mount that is bolted to the C-channel frame with a Huck® bolt. The axle-connecting rods are parallel for vertical motion and cross linked for lateral stability.

Air bag/shock suspension

Air bag/shock suspension

The R4023 Sprayer's standard suspension provides for 152 mm (6 in.) of travel at the air bag. The air springs are underneath the frame; therefore, visibility of the rows passing underneath is free of suspension components.

The air springs are adjusted by adding or removing air through a standard air-stem valve on top of each spring or, if the sprayer is equipped with auto air-spring leveling, the air springs will inflate to the optimum level for the best-possible ride.

| Code | Description |

| 7030 | Standard Shock |

| 7035 | Soft Shock (Rough Terrain Application) |

The auto air-spring leveling system is standard equipment. This feature maintains ride height, ensuring 102 mm (4 in.) of travel up and down at all times for 203 mm (8 in.) of total travel. The operator does not have to individually fill each bag or deflate each bag for transport, saving as much as 10 minutes. A switch located near the solution loading system deflates all four bags at one time. Once the machine is running, the on-board air compressor automatically inflates the bags to the optimal set ride height.

Huck is a trademark of Alcoa Incorporated.

Wide axle, 234 cm to 307 cm (92 in. to 121 in.)

Wide axle, 234 cm to 307 cm (92 in. to 121 in.)

Narrow axle, 183 cm to 224 cm (72 in. to 88 in.)

Narrow axle, 183 cm to 224 cm (72 in. to 88 in.)

Two axle widths are available to best fit a variety of cropping row widths.

The narrow width axle has a tread width from 183 cm to 224 cm (72 in. to 88 in.) and a clearance of 112 cm (44 in.). The wide axle has a tread width from 234 cm to 307 cm (92 in. to 121 in.) and a clearance of 127 cm (50 in.). Axle range for wide machines varies slightly depending on the option (hydraulic vs. manual tread adjust) that is being used.

NOTE: In order to achieve 229-cm (90-in.) tread spacing, IF320/80R42 tires must be used with AN401678 rims. Please see your local John Deere Dealer for more information.

With these tread spacings, the R4023 Sprayer holds an impressive 46-54 weight split when unfolded, fully loaded. This weight split helps to reduce compaction through the field and keeps the power to the ground.

The wide axle is ideal for the Midwest grain farmer. With the wide axle option, the operator can straddle three rows at 76.2-cm (30-in.), 81.3-cm (32-in.), 86.4-cm (34-in.), 91.4-cm (36-in.), 96.5-cm (38-in.), or 101.6-cm (40-in.) spacing or four rows at 76.2-cm (30-in.) spacing.

The narrow axle is ideal for the cotton or specialty crop farmer. With the narrow axle option, the operator can straddle two rows at 91.4-cm (36-in.), 96.5-cm (38-in.), or 101.6-cm (40-in.) row spacing.

Having the optimal weight distribution results in a lighter footprint leaving less compaction and less damage to the field, allowing the operator to get into the field earlier.

The R4023 Sprayer was built with the optimal weight distribution.

R4023 Self-Propelled Sprayer |

Front weight |

Rear |

Machine weight |

Weight |

|

|

Total |

Total |

Total |

Front |

Rear |

| Base machine empty with booms folded, 24.3-m (80-ft) boom | 5,048 (11,105) |

3,227 (7,100) |

8,275(18,205) |

61 |

39 |

| Base machine empty with booms unfolded, 24.3-m (80-ft) boom | 4,220 (9,285) |

4,055 (8,920) |

8,275 (18,205) |

51 |

49 |

| Base machine full water with booms folded, 24.3-m (80-ft) boom | 5,912 (13,006) |

5,036 (11,079) |

10,948 (24,086) |

54 |

46 |

| Base machine full water with booms unfolded, 24.3-m (80-ft) boom | 5,146 (11,320) |

5,802 (12,765) |

10,948 (24,086) |

47 |

53 |

R4023 operator station

R4023 operator station

When operators first enter the R4023 cab, they notice that there have been significant changes made from previous years. Key sprayer controls are more easily accessible to the operator on the redesigned CommandARM console, and the multi-function lever has a more ergonomic fit and feel.

The multi-function lever has six reconfigurable buttons, a scroll to select speed range, and allows operators to better manage their headlands with the HMS™ headland management system button.

To finish out the upgrades, the display has been upgraded to a larger, faster, more user-friendly G5Plus CommandCenter™ Display, which allows operators to efficiently capture, manage, and transfer data.

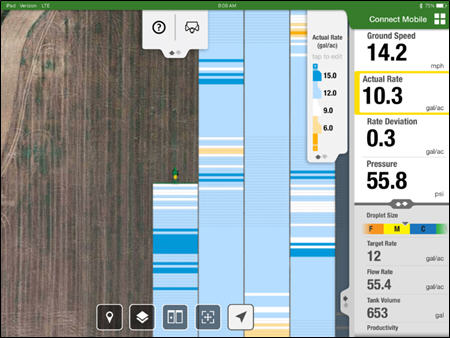

Connect Mobile actual rate map and pressure map in split screen gives the operator deeper understanding of machine performance

Connect Mobile actual rate map and pressure map in split screen gives the operator deeper understanding of machine performance

John Deere Connect Mobile is a solution that utilizes an Apple® iPad® tablet in the cab that provides the operator a better understanding of the sprayer’s performance. Connect Mobile documents and displays several sprayer performance attributes, helping the operator monitor and more easily detect problems that can occur while spraying. Connect Mobile also has a common user interface that makes it easy to use between different pieces of John Deere equipment. Once the job is done, the iPad with the spraying data can be utilized to perform basic crop scouting activities in the field.

Monitor key performance indicators in map layers and dashboard tiles such as:

Connect Mobile hardware is factory installed on all model year 2022 and newer 408R, 410R, 412R, 612R, 616R, 400 and 600 Series Sprayers and dry machines well as model year 2017 to 2022 R4030, R4038, R4045, and R4060 Sprayers, making it easy to get started with Connect Mobile.

Learn more about Connect Mobile in the Field and Crop Solutions section within the Precision Ag Technology product line and how it can improve the quality of a spraying job.

iPad and Apple are trademarks of Apple Inc.

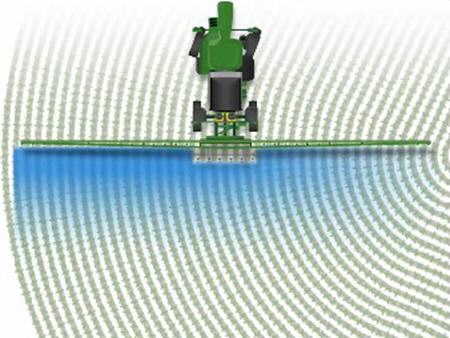

Turn compensation mode

Turn compensation mode

Individual nozzle control mode

Individual nozzle control mode

Fertilizers and crop protection products are too expensive to waste, and seed is too valuable to risk over- or under-treating. To help make sure your solution is getting to the crop at exactly the right rate and droplet size across a wider range of speeds, look to ExactApply nozzle control system.

The heart of the ExactApply system is a six-nozzle turret with multiple modes of operation to help maintain target rate and pressure. From the cab, operators can choose:

By maintaining a target rate and pressure over a wider range of speeds, ExactApply lets you cover up to 20 more acres per hour (based on a 3.2-km/h [2-mph] increase in operating speed) with more consistent spray deposition, saving you input costs and preserving more of your crop’s yield potential.

New for model year 2026, John Deere is introducing ExactApply Multi-Rate which enhances our ExactApply nozzle capabilities by enabling the delivery of multiple rates across the eleven sections of the boom in a single pass, regardless of the boom length. This innovation allows for improved rate resolution, particularly while utilizing application prescriptions. Now operators can target specific zones for optimized application, which will enhance crop consistency across varying field conditions. Critical uses include tailored fertilizer for small grains and corn, based on plant and soil conditions, such as top-dressing in wheat, as well as pre or post emerge nutrients for corn.

ExactApply Auto Select Pulsing with A+B Nozzle Switching, enables the Multi-Rate function, expanding performance and speed ranges while ensuring proper droplet size and placement. It also significantly increases the rate range during curve compensation, allowing versatile utilization across all three nozzle configurations within the eleven sections for optimal application.

ExactApply Multi-Rate is a software update included in order code 4985- John Deere ExactApply Nozzle Control and available on model year 2026 R4023, 408R, 410R, 612R, as well as the 616R sprayers. It is also compatible with model year 2022 and forward. A+B Switching and Pulsing compatible with all ExactApply configurations.

ExactApply is available as a factory-installed option, as well as through Aftermarket Attachments and Precision Upgrades.

ExactApply aftermarket attachment kits are available for 4 Series Sprayer models.

Precision Upgrades for ExactApply are available for 400, 600, and 4 Series Sprayer models.

Monitor machines on the go and make adjustments when it matters most

Monitor machines on the go and make adjustments when it matters most

Connectivity provides data that drives better decisions

Connectivity provides data that drives better decisions

Producer needs and their success is John Deere’s focus. As functionality becomes more accepted and even expected, that functionality moves from being optional to being included with the machine. In model year 2019, AutoTrac™ guidance and documentation was included on machines equipped with a 4600 CommandCenter™ Display. Five years of JDLink is also included with the purchase of all model year 2020 and newer machines equipped with a 4G LTE Modular Telematics Gateway (MTG). The functionality of JDLink on these machines includes everything that was previously included with JDLink Access + Remote Display Access (RDA) and JDLink Connect subscriptions. This added connectivity enables customers to realize the value of a connected machine more easily.

To use JDLink, the following is required:

Connected Support technology

Connected Support technology

When you buy John Deere equipment, you expect reliability. You also know that problems can happen, and a product is only as good as the support behind it. That’s why John Deere equipment is prepared with technology that senses potential issues and can alert you and your dealer promptly—in the cab or anywhere you are.

John Deere Connected Support is a revolutionary change to support that leverages technology and the connectivity of JDLink™ telematics to prevent downtime and resolve problems faster. These tools decrease downtime by an average of 20 percent, enabling faster responses to unexpected problems and reducing technician trips to your machine. For some issues, unplanned downtime can even be prevented altogether through prediction of the issue.

With your permission, John Deere Connected Support:

With more than a decade of experience leveraging connectivity to solve problems, no one else has the experience, tools, and knowledge to keep you running as John Deere and your John Deere dealer can. Connected Support is an in-base feature on all John Deere products with factory- or field-installed JDLink.