Heavy-duty adjustable downforce springs

Heavy-duty adjustable downforce spring

Heavy-duty adjustable downforce spring

Planter row-unit downforce is an important factor to ensure consistent and proper depth control. The heavy-duty adjustable downforce feature provides up to 181.4 kg (400 lb) of downforce. There are four settings available to allow the operator to choose the amount of downforce required for the condition: 0 kg (0 lb), 56.7 kg (125 lb), 113.4 kg (250 lb), and 181.4 kg (400 lb).

Compatibility: 1705, 1715, 1725, 1735, 1755, 1765, 1765NT, 1775 Flex, and 1785

Standard pneumatic downforce system

Pneumatic downforce provides convenient, simple adjustment of downforce for the whole planter from one location. The amount of downforce applied is infinitely adjustable from 0 to 181.4 kg (0 to 400 lb). Pneumatic downforce provides more consistent downforce throughout the range of row-unit travel than mechanical spring downforce systems.

Features include:

- 9.5-mm (3/8-in.) air delivery line instead of the 6.4-mm (1/4-in.) line used on model year 2010 and older planters.

- Air compressor assembly increased duty cycle. With this compressor, it provides a 47 percent increase in maximum air flow delivery compared to the prior air compressor.

- Pneumatic air bags with 9.5-mm (3/8-in.) air line inlets that have greater durability.

Pneumatic downforce spring

Pneumatic downforce spring

Each row-unit has a single rubber air bag located between the parallel arms. The air bags are hooked in parallel so that air can be added or released from all rows at once from one location.

The individual pneumatic downforce air bag assemblies, air compressor units, and 9.5-mm (3/8-in.) delivery lines are also available as an attachment for field conversion.

Pneumatic downforce compressor and gauge

Pneumatic downforce compressor and gauge

An improved compressor is used to charge the pneumatic system. This compressor can be located on the planter frame or in the tractor cab if desired. A gauge at the compressor indicates the amount of downforce being applied.

From the factory, integral planter models with pneumatic downforce will have an improved air compressor assembly with an in-cab mounting bracket, except for the 1725 16-row and 1725 Central Commodity System (CCS™) twin-row planters, which will have the air compressor assembly mounted on the planter frame. For drawn planter models, the 1755, 1765, 1765NT, 1775 Front-Fold, and 1785 Drawn Planters will have the air compressor assembly installed either on the outer hitch or wing frame members when the pneumatic downforce system is installed.

Base equipment on: 1705, 1715, 1725, 1735, 1755, 1765, 1765NT, 1775 and 1785.

Integrated pneumatic downforce system

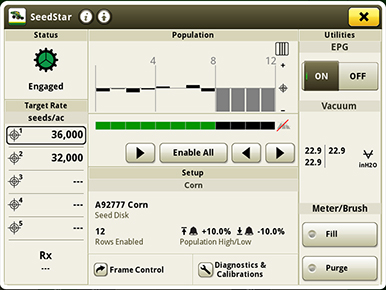

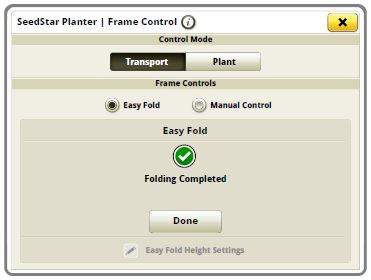

The functional features of the integrated system are the same as the standard pneumatic system, explained above, with the addition of control through the GreenStar™ display.

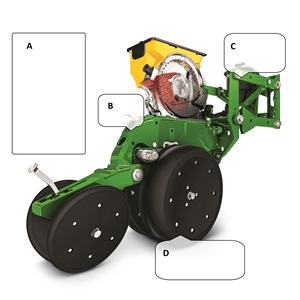

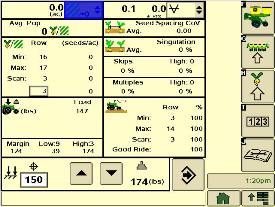

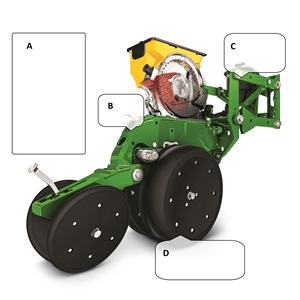

Downforce and margin example

Downforce and margin example

- A - Margin – amount of additional downforce applied to a row-unit above and beyond what is required for penetration to achieve planting depth. This additional weight will ride on the depth gauge wheels. 54.4 kg (120 lb) + 36.3 kg (80 lb) = 90.7 kg (200 lb) – 68 kg (150 lb) = 22.7 kg (50 lb) of margin

- B - Weight of row-unit - 54.4 kg (120 lb)

- C - Downforce – force that is applied to the row-unit by the air bag circuit - 36.3 kg (80 lb)

- D - Resistance from soil - 68 kg (150 lb)

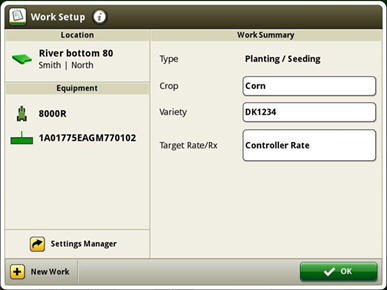

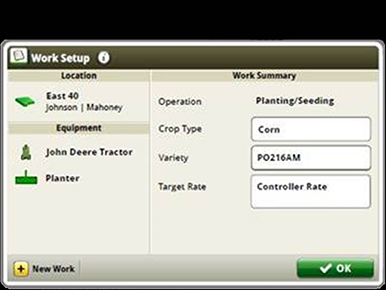

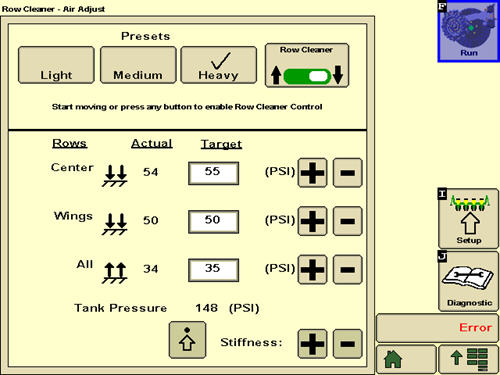

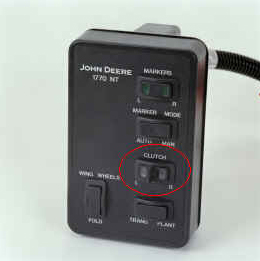

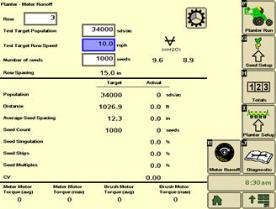

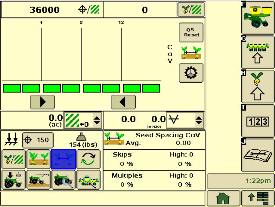

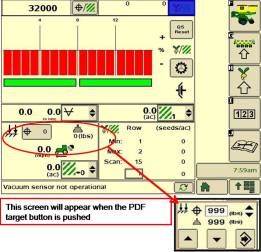

System control with the GreenStar display

Pneumatic downforce control in 17-212 Display

Pneumatic downforce control in 17-212 Display

Air compressor mounted on 1775NT outer hitch

Air compressor mounted on 1775NT outer hitch

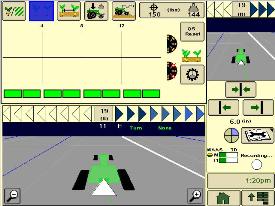

On 1725 16-row, 1725 CCS TR, 1775NT, 1775NT CCS, 1795, DR, and DB Series Planter models, the air compressor will be mounted on the outer hitch or frame assembly. Since the air compressor assembly is mounted on the outer hitch (as noted in the picture above) or frame, adjustments for row-unit downforce and related system pressures will be made electronically with the GS display.

When adjusting the amount of row-unit downforce using the GS display, the operator will select the amount of downforce (kg [lb]) to be applied across the planter. Depending on the soil conditions at hand, the operator might need to adjust the relative amount of row-unit downforce being applied during the planting operation. The integrated pneumatic downforce controls within the GS display will only allow for set-point operation and not automatic control as the planter is operating in different soil conditions. The pneumatic downforce system does not have the capability to automatically adjust downforce.

Active pneumatic downforce

Active downforce compressor assembly

Active downforce compressor assembly

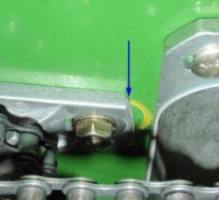

Hydraulic motor

Hydraulic motor

A hydraulically driven compressor works with the SeedStar™ 3 HP system and SeedStar XP system to automate downforce control. Just set the row-unit target margin value and the active pneumatic downforce system works automatically. The system will make sure the planter maintains this value, achieving precise soil penetration, and consistent planting depth, without sidewall soil compaction. From the factory, the system is set at a 45.4-kg (100-lb) target downforce margin, but may be modified for varying field conditions. This frees the operator from constantly making manual downforce adjustments as conditions change.

This system offers a split-rank control feature for 1795 and DB Split-Row Planters. On split-row planters, active downforce will control the front and rear rows independently. This compensates for differing downforce requirements between the ranks that can be caused by things like different tillage or insecticide attachments and will help maintain an accurate planting depth and consistent margin across all the rows.

Active pneumatic downforce is available as factory installed or as an attachment for field conversion.

On-board air storage

Onboard air storage installed on 1775NT 24R30

Onboard air storage installed on 1775NT 24R30

The 1725 16-row, 1725 CCS TR, 1775NT, 1775NT CCS, 1795, DR, and DB Series planters will have onboard air storage to increase the overall response time when making a row-unit downforce adjustment from the GS display. The onboard air storage is comprised of an 18.9-L (5-gal.) storage tank with valve assembly.

Base equipment on: 1725 CCS, 1725 16-row, 1725T, 1775NT, 1775NT CCS, 1795, DR, and DB Series Planters with MaxEmerge™ 5 row-units. MaxEmerge 5e and ExactEmerge™ equipped planters come with active pneumatic downforce in base.

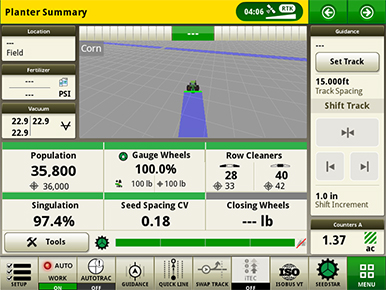

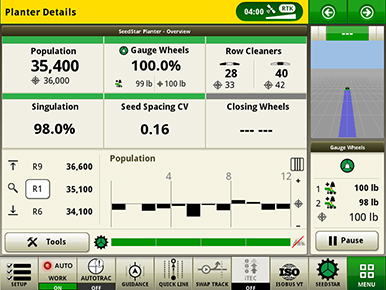

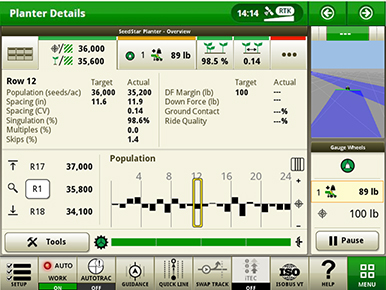

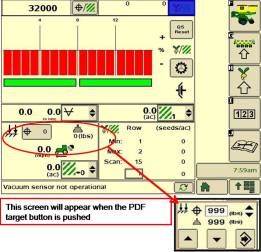

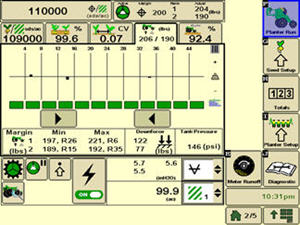

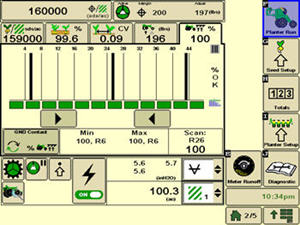

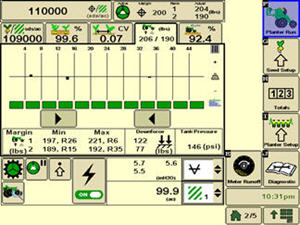

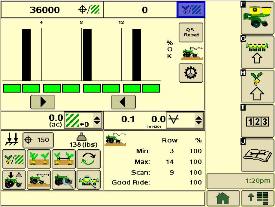

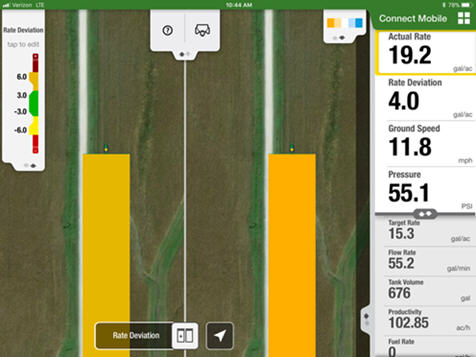

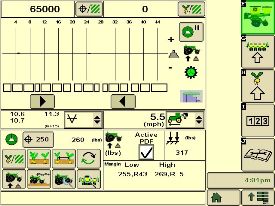

SeedStar XP row-unit downforce planter run page

SeedStar XP downforce planter run page

SeedStar XP downforce planter run page

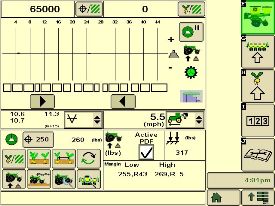

Active downforce control is integrated into SeedStar XP and SeedStar 3 HP monitoring systems.

Margin is the amount of weight riding on the depth gauge wheels that ensures desired firming of the seedbed as set by the operator.

Once a target margin has been defined, enter the value into SeedStar XP or SeedStar 3 HP and let active downforce do the rest. The system will actively adjust the air pressure in the air bags to maintain a constant margin across the planter. The changes in air pressure will change the amount of downforce placed on the row-unit, compensating and reacting for varying conditions through the field whether it is different tillage practices, soil types, or moisture.

Optional equipment on: 1775NT, 1795, DB, and Orthman custom models with MaxEmerge 5e and ExactEmerge row-units.

Hydraulically driven compressor

Hydraulic motor

Hydraulic motor

Pneumatic valve

Pneumatic valve

The hydraulically driven air compressor can deliver up to eight times the air flow, allowing for more and faster downforce changes to be made. This more robust design features a 37.8-L (10-gal.) storage tank across all models with active downforce.

At approximately 15.1 L/min (4 gpm), hydraulic demands are low and ties into the machine’s lift and CCS hydraulic circuit so it does not require any additional selective control valves (SCVs). The SeedStar XP and SeedStar 3 HP monitoring systems work with the compressor and valve assembly to regulate air to downforce springs, enabling the active control.

Another feature of John Deere active downforce is the ability for the pneumatic valve to independently control split-rank machines. This system senses the downforce needs from the front and rear ranks separately and independently adjusts air pressures with the dual-rank pneumatic valve when equipped. Active pneumatic downforce requires SeedStar XP or SeedStar 3 HP to enable active control.

Base equipment on: All MaxEmerge 5e and ExactEmerge equipped planter models.

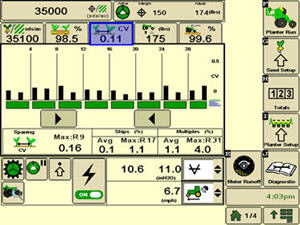

Individual row hydraulic downforce (IRHD)

IRHD has been specifically designed to meet the needs of producers that are looking to adjust to the toughest field conditions and provide maximum yield potential from field to field, season after season. IRHD works as a closed-loop downforce system that reacts quickly on an individual row basis to changing soil conditions supporting increased ground contact, which can lead to improved seed depth consistency. When setting planter downforce margin, the system will apply the needed downforce by row to maintain ground contact. From the factory, the margin will be set at 45.4 kg (100 lb), changes may be required based on varying field conditions.

The system allows operators to maintain gauge wheel ground contact leading to desired seed depth placement. IRHD can adjust five times per second and make adjustments of 45.4 kg (100 lb) in less than a second. The system has a total range of applied downforce from 22.7 kg (50 lb) to

204.1 kg (450 lb) and utilizes the power beyond circuit on the tractor. IRHD is 58 percent faster than the active pneumatic downforce solution. Fast reaction and increased ground contact can lead to improved emergence. With uniform emergence, some studies have shown a yield impact from 5 percent to 9 percent.

IRHD is controlled through the Gen 4 4600 CommandCenter™ Display or 4640 Universal Display with SeedStar 4HP. As shown below, operators can view ground contact or applied downforce using the toggle button.