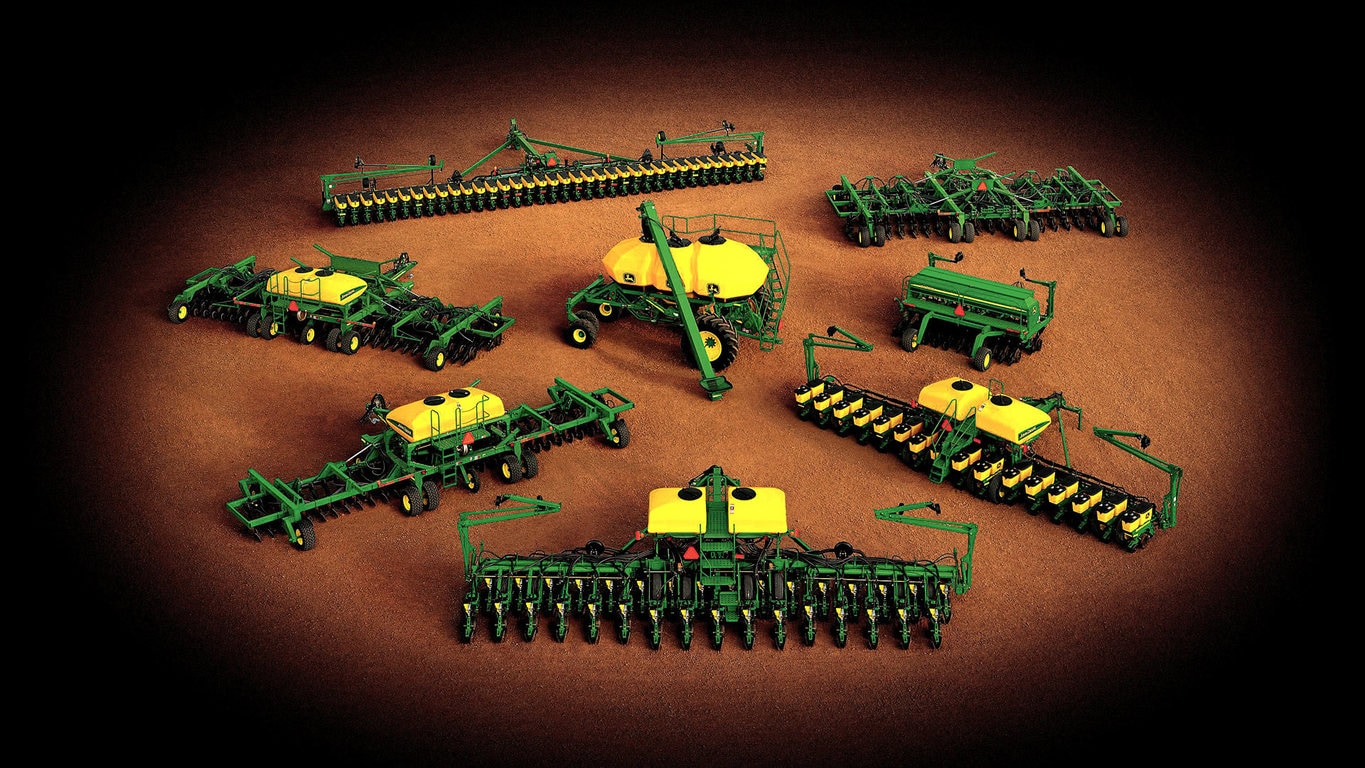

MaxEmerge 5 with 56-L (1.6-bu) hopper plus insecticide

MaxEmerge 5 with 56-L (1.6-bu) hopper plus insecticide

MaxEmerge 5 with mini hopper

MaxEmerge 5 with mini hopper

The MaxEmerge family of row-units have never seen a more versatile and efficient design until the MaxEmerge 5. The 5-family row-units improve productivity, increase uptime and lower the cost of ownership like never before. Producers now have that all-in-one meter and row-unit straight out of the factory with one order, increasing their bottom line.

The MaxEmerge 5 row-unit looks distinctively different than previous MaxEmerge products. The changes were not done just for better looks, what was already an industry-leading row-unit in performance and serviceability just got even better.

The field-proven designs of both the MaxEmerge XP and Pro-Series XP™ were combined into one interchangeable meter design. Advanced manufacturing technology and world-class testing techniques were used to design a planter row-unit that has increased strength and longer-wearing parts, plus is easier to service, decreasing downtime during the grower’s most crucial season.

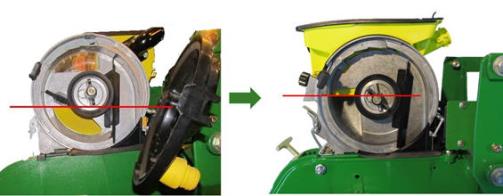

Serviceability and changing crops has always been a focus of downtime and potential seed loss. MaxEmerge XP Row-Units (shown on the left) are designed with the meter and hopper as one component. The frame covers the meter so that it cannot be accessed. Cleanout of excess seed requires the operator to take the entire hopper off of the row-unit and to turn it upside down. The MaxEmerge 5 meter (shown on the right) is accessible without having to remove the box. The MaxEmerge 5 design allows large hoppers to be cleaned out the same as mini-hoppers, simply by opening the meter dome and catching the seed as it falls out. This nice improvement will allow operators to change seed varieties easier and three times faster than it took them on the previous MaxEmerge XP units and provide more uptime during the tight planting window.

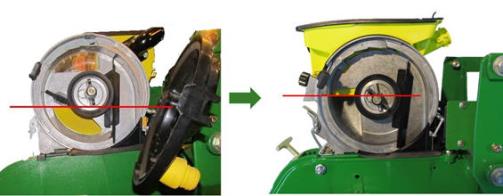

MaxEmerge 5 meter shape

MaxEmerge 5 meter shape

The MaxEmerge 5 meter shape has also been redesigned for better seed flow. The model year 2014 and older mini-hopper is starved of seed when operating on side-hills greater than 9 degrees. The enhancements made to the mini-hopper design with this program allow the planter to successfully operate on side hills up to 14 degrees. This correlates to the planter able to run on a 55 percent greater slope without loss in meter performance.

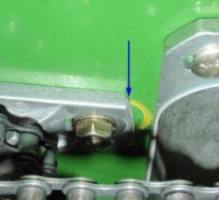

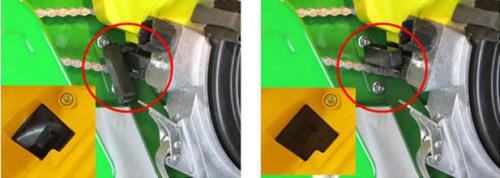

Hopper shutoff

Hopper shutoff

Also, to help with meter access of 56-L and 106-L (1.6-bu and 3-bu) hoppers the hopper shutoff feature was added. With the shutoff engaged, the meter cover can be opened without first having to remove all of the seeds from the hopper. Lever down, the seed flow is on, lever horizontal and the seed flow is off.

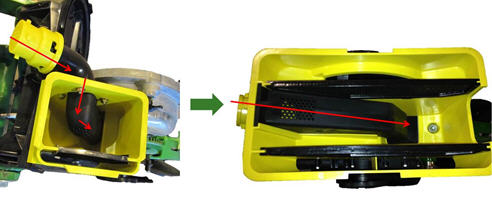

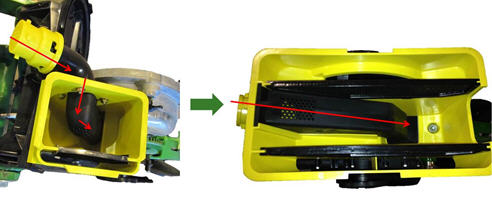

MaxEmerge 5 mini-hopper

MaxEmerge 5 mini-hopper

There are significant changes to the MaxEmerge 5 Mini-Hopper. One update is to the straight feed from the Central Commodity System (CCS™) hose to the mini-hopper to ensure a continuous free flow of seeds. As seed size and treatment grow, producers will not experience potential plugging issues. And inside the meter, the air is cleaner than ever because the vacuum air source has been changed, drawing from inside the CCS tank where there is far less debris. Cleaner meters lead to higher planting performance.

Ductile iron-cast shank

Ductile iron-cast shank

The shank of the row-unit is the foundation of planter performance. All ground-engaging functions of the row-unit radiate from it.

The shank must be a pillar of strength and must not bend or twist under load. The perfect seed furrow, precision seed spacing, and alignment of the closing systems all depend on the row-unit shank being rock solid. The row-unit shank must have the strength to plant in all field conditions, acre after acre, year after year.

It all starts with the ductile iron-cast shank. Ductile iron casting is a unique high-tech process that produces a single-piece row-unit shank that replaces the traditional 13-piece welded shank.

The properties of ductile iron castings are such that they deflect without bending, withstand great impact without cracking, and can be machined to close tolerances for precise alignment of mating components perfect properties for a row-unit shank.

A ductile iron-cast shank is a foundation of higher quality and higher strength for a John Deere row-unit.

The row-unit head is also designed using the ductile iron-casting process. The row-unit head provides the mating joint between the row-unit parallel arms and the row-unit shank. It is also the upper attaching point for the seed meter and seed hopper.

Ductile iron casting of the row-unit shank and head assembly provides a row-unit that is 25 percent stronger than welded row-units.

In addition to strength, the cast shank also promotes better alignment of all row-unit components. The one-piece casting with its machined surfaces eliminates the variable tolerances associated with welded assemblies. Properly aligned components not only function better in the field, they also have a longer wear life.

The lower portion of the MaxEmerge 5 ductile iron shank incorporates a bayonet-style mount for the seed tube guard, offering greater ease of service. Simply slide the guard onto the bayonet mount with a quick twist and lock to attach the guard. Once the opener blades are in place, the seed tube guard is in position, ready for the seed tube.

Tru-Vee opener blades and bearings

Tru-Vee opener blades and bearings

One of the trademark capabilities of John Deere planters has always been the ability of the Tru-Vee™ openers to provide a perfect seed furrow acre after acre in all types of field conditions.

The MaxEmerge 5 row-unit builds on this tradition with components that offer a longer wear life and reduced maintenance time, and provide value to the grower in reduced cost of ownership over the life of the planter.

The thickness of the Tru-Vee opener blades was increased from 3.0 mm to 3.5 mm (0.12 in. to 0.14 in.) with the introduction of the XP row-units and maintained with MaxEmerge 5. This increased opener blade thickness will provide 20 percent longer wear life.

The MaxEmerge 5 row-unit also provides better Tru-Vee opener bearings for longer life. The double-row ball bearing provides up to three times the wear life as the single-row bearing.

To complete the world-class Tru-Vee opener assembly, the rivets that secure the bearing and hub to

Depth adjustment T-handle

Depth adjustment T-handle

John Deere planters provide consistent seed depth control in all field conditions. Depth control is a function of the Tru-Vee openers, the downforce system, and the gauge wheel assembly.

The gauge wheel itself is made of durable nylon composition with a concave profile. This profile gently firms the sides of the seed furrow, ensuring a well-defined trench. The concavity also reduces rocks and residue being picked up and thrown onto the drive chains and row-units, and helps to prevent rooster tailing of soil.

The bolt-through design utilizes an open bearing in the gauge wheel that allows an attaching bolt to pass through the wheel to the threaded hole in the gauge wheel arm. This simple bolt-through design provides for a positive attachment of the gauge wheel to the gauge wheel arm and allows quick removal of the gauge wheel for service.

Adjustability of the row-unit is critical to good performance. MaxEmerge 5 row units are the most user-friendly, adjustable units in the industry.

- More available downforce options than any row unit in the industry

- Single downforce springs, non-adjustable, 41 kg (90 lb) of downforce

- Double downforce springs, non-adjustable, 82 kg (180 lb) of downforce

- Adjustable heavy-duty downforce, four settings, 0 kg (0 lb), 57 kg (125 lb), 113 kg (250 lb), and 181 kg (400 lb) of downforce

- Pneumatic downforce, infinitely variable from 0 kg to 181 kg (0 lb to 400 lb) of downforce

Rubber tire closing system

Rubber tire closing system

Cast wheel closing system

Cast wheel closing system

Rubber tire closing systems are used for most conventional, minimum-till, and no-till planting conditions. The spacing between the wheels is adjustable so the closing system can meet the needs of those who want to plant small seeds at shallow depths.

The wheels can also be staggered fore and aft to enhance residue flow. Four levels of spring force are available and are easily set with the integrated T-handle adjustment. A lower force spring can be obtained from parts, if a lower amount of force is required.

Additional closing wheel options include:

- Cast closing wheels, for tough to close conditions

- Disk closing, for shallow planting depths

- Drag closing, for crust-and-bake conditions

- Closing wheel frame less wheels, for growers desiring to use aftermarket closing wheels

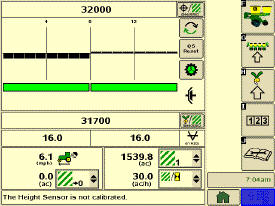

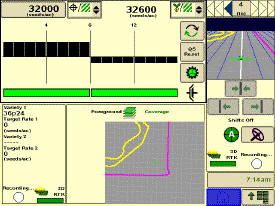

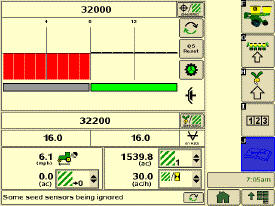

Performance |

Uptime |

Cost of operation |

- Straight inlet to mini-hopper providing a smooth, less resistant flow of seed.

- Vacuum air source from inside the CCS tank on mini-hoppers for optimal clean meter productivity.

- Seed pool size increase provides more opportunity to select seeds and gives the meter optimal performance on slopes up to 14 degrees in any direction.

|

- Hopper shut off on 56-L and 106-L (1.6- and 3-bu) hoppers allow producers to access meters without emptying the hopper or experiencing unnecessary seed loss.

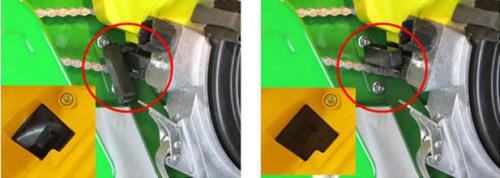

- Knockout wheel and scraper installation makes crop changeover quicker than ever, no more tools and 3 times faster than previous meters.

|

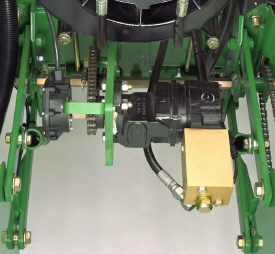

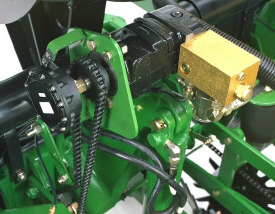

- Granular insecticide allows mini-hopper operators ability to put down product in the same pass, reducing fuel costs and potential compaction.

- Pro-Shaft™ drive on both insecticide and seed metering provides longer life than chain drive in high residue applications.

- Gauge wheel pivot arm improvements increase life and reduce parts costs.

|