HD40XHeader

- 12,20 m Cutting width

- 1200 mm Draper belt width

- 72 - 228 m/min Draper Speed

- Dual Knife Drive with 2080 cuts/min

- 1200 mm Table length

Cutting crop to a consistent stubble height improves the loading of the combine which delivers better separation and cleaning. This in turn makes sure only evenly cut and spread straw particles are left behind the combine. It also makes it easier for tillage tools to prepare a better seedbed which helps seed establishment and ultimately, higher germination rates.

X Series Combine with 15.2-m (50-ft) Hinged Draper

X Series Combine with 15.2-m (50-ft) Hinged Draper

Harvest acres faster than ever before with a 15.2-m (50-ft) John Deere Hinged Draper built off the 700D and 700FD Drapers’ proven foundation.

X Series Combine with 15.2-m (50-ft) Hinged Draper

X Series Combine with 15.2-m (50-ft) Hinged Draper

John Deere HDR and HDF Drapers follow the ground by pivoting, gliding, and flexing over uneven fields to provide the best cut possible.

MacDon is a trademark of MacDon Industries Ltd.

The multi-crop HDX Draper Platform

The multi-crop HDX Draper Platform

A true multi-crop header is your insurance to handling your crops with one header. The HDX is the only header that can handle all crops and conditions without compromise from high-yielding, high-moisture, bushy oilseed rape to short and dry peas that need to be cut low to the ground.

The goals for a successful harvest are simple: harvest on time and put all the grain in the tank from all your crops. The John Deere HDX Draper is designed to take those goals to another level.

The HDX Draper combines the benefits of active feeding from draper belt technology with an extended table for harvesting tall or difficult bushy crops such as tillered oilseed rape. This results in increased combine performance with a header for all different crop conditions and types.

Harvest more grain in more crops with one header

Harvest more grain in more crops with one header

Reel harvesting standing crop

Reel harvesting standing crop

Reel harvesting downed crop

Reel harvesting downed crop

On top of a tighter reel-to-cutterbar relationship, the reel also can reach out farther and lower with a 24 percent increase in reel torque compared to the 700FD HydraFlex™ Drapers. This draper makes quick work of downed and lodged crops.

Reel positioned down

Reel positioned down

Reel positioned up

Reel positioned up

Reel range measurements:

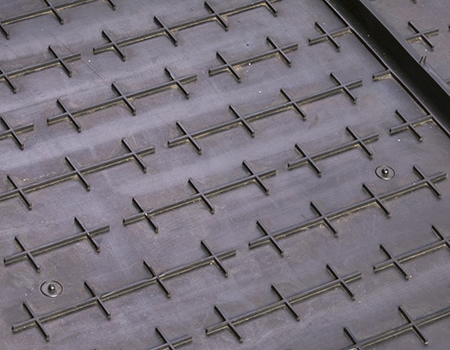

Reduce cutterbar loss by 25 percent with John Deere Grain Saver Draper Belts compared to standard draper belts. A special crosshair design on the belt helps trap free grain before it can roll past the cutterbar onto the ground. It is a very simple yet smart design that producers will appreciate in the field after seeing their elevator ticket.

Grain saver belt reduces loss

Grain saver belt reduces loss

Grain saver belts reduces loss

Grain saver belts reduces loss

Cleat design of the draper belt

Cleat design of the draper belt

Extended draper belt for high performance in cereals and rapeseed

Extended draper belt for high performance in cereals and rapeseed

The HDX Series Draper was designed to provide producers who grow cereal crops as well as high-volume rapeseed with a true high-performance multi-crop draper. It combines the benefits of the active feeding draper technology with the benefits of an extended cutterbar platform.

Deeper platform with 1200-mm (47.2-in.) draper belts

Deeper platform with 1200-mm (47.2-in.) draper belts

Harvesting in the field

Harvesting in the field

The toolless, quick-attach side knives enable operators to convert from cereal dividers to side knives in less than 5 minutes. This is important for operators during times of the year where they are switching between crops throughout the harvest day.

Side knife

Side knife

Dual side knives installed on draper

Dual side knives installed on draper

Side knife storage bracket

Side knife storage bracket

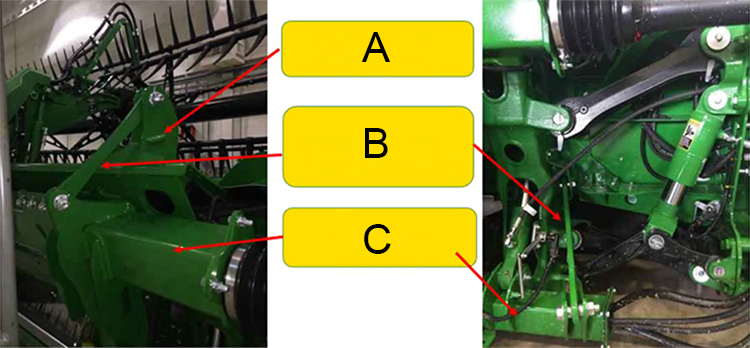

Experience consistent and smooth terrain following performance with a draper integrated attachment and center frame that enables passive terrain following, resulting in less missed crop and a more consistent stubble height.

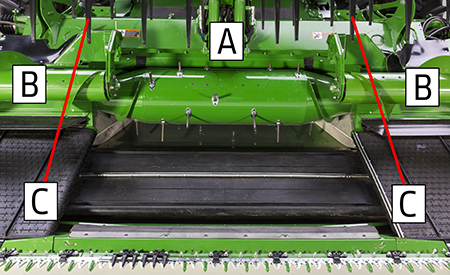

Center frame suspension system: center frame (A), center frame linkages (B), attachment frame (C)

Center frame suspension system: center frame (A), center frame linkages (B), attachment frame (C)

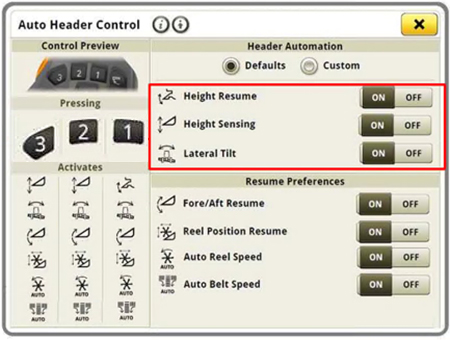

Automated height sensing

Automated height sensing

NOTE: HDR and HDF models always require auto header height sensing to be on, but for the best performance, all automated features should be on.

MacDon is a trademark of MacDon Industries Ltd.

Reduce passes through washouts, hills, bottoms, and terraces in the field with a hinged frame draper, which allows operators to take and most importantly cut more full-width passes in the fields.

Hinged frame on HDR and HDF Drapers

Hinged frame on HDR and HDF Drapers

Hinged frame on HDR and HDF Drapers

Hinged frame on HDR and HDF Drapers

Draper center frame (A), wings (B), and hinged points (C)

Draper center frame (A), wings (B), and hinged points (C)

Reel is closer to the cutterbar

Reel is closer to the cutterbar

| Draper model | John Deere HD Series (+/- 5 degrees) |

MacDon (+/- 2.5 degrees) |

CLAAS® CONVIO (+/- 0 degrees) |

| Valley or washout |  |

|

|

| Crest or ridge |

Reel cutterbar flat

Reel cutterbar flat

Reel cutterbar up

Reel cutterbar up

Reel cutterbar down

Reel cutterbar down

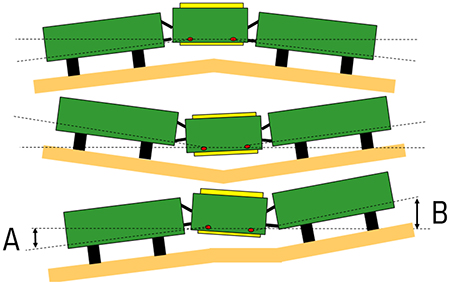

10 degrees of wing motion (A is -5 degrees of wing motion and B is +5 degrees of wing motion)

10 degrees of wing motion (A is -5 degrees of wing motion and B is +5 degrees of wing motion)

All the frames (left wing, center, and right wing) being independent from one another allow for a wide range of motion for the header to maneuver. There are 10 degrees of travel between the wing frames and the center frame (5 degrees up and 5 degrees down).

MacDon is a trademark of MacDon Industries Ltd. CLAAS is a trademark of CLAAS KGaA mbH.

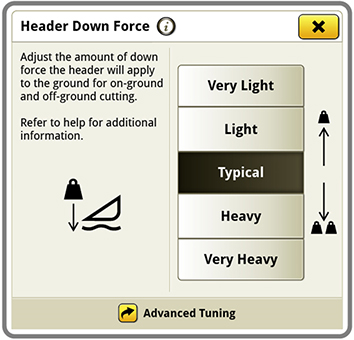

Ground conditions change day to day, field to field, and hour to hour. Ensure ground conditions do not make operators come to a halt with the ability to quickly adjust header down force. Five ground condition settings let operators adjust the draper to follow fields better without leaving the cab.

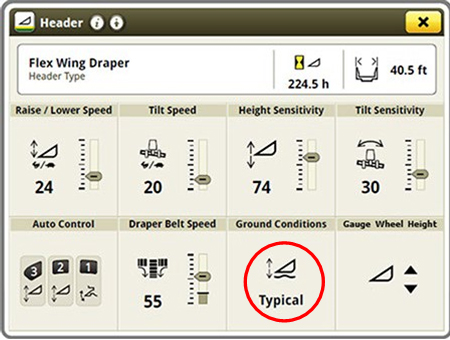

Select the header down force button to change the setting

Select the header down force button to change the setting

Header down force settings on display

Header down force settings on display

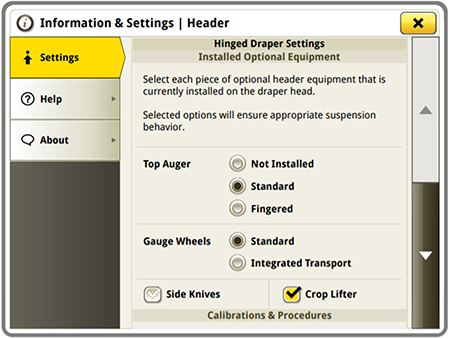

All attachment frame and draper frame wings suspension tuning is performed within the header application on the 4600 CommandCenter™ Display.

Automatic header height sensing mode needs to be active in order to make an adjustment to header down force. There is not a pressure reading displayed to the operator as there use to be with HydraFlex™ technology. The operator simply selects the current ground conditions for header operation.

These are factory settings for suspension pressures for five different conditions:

The heavier the setting, the more rigid the suspension.

Configure optional equipment in the Installed Optional Equipment screen

Configure optional equipment in the Installed Optional Equipment screen