6115ETractor

- PowerTech™ E (Tier 3) 4.5L (276 cu in.)

- Category 2, 3-point hitch

- MFWD / 2WD

- Open station / cab

John Deere 6E Series Tractors feature the reliable and proven 4.5L (274.6 cu in.), two-valve PowerTech E engine.

The PowerTech E engine, used in 6100E, 6115E, and 6130E models, are diesel engines that can deliver up to 25 percent torque rise.

Model |

Engine |

Emission level |

Engine displacement |

Rated engine speed |

6100E |

PowerTech E |

Tier 3 |

4.5L (274.6 cu in.) |

2100 rpm |

6115E |

PowerTech E |

Tier 3 |

4.5L (274.6 cu in.) |

2100 rpm |

6130E |

PowerTech E |

Tier 3 |

4.5L (274.6 cu in.) |

2100 rpm |

These engines are designed for performance, long life, and low maintenance costs. The two-valve engine design of the PowerTech E provides excellent torque, fuel efficiency, and durability. The PowerTech engine delivers:

Clean performance Latest engine technology True customer value

The PowerTech E also features a rotary injection pump and mechanical governor.

The hood tilts to open wide, allowing unencumbered engine compartment access. An easy-reach tether cord allows access to effortlessly close the hood. Overriding the two gas struts permits the hooding up to 90 degrees. Unhooking the tether from the radiator support allows the operator to open the hood even further to provide better access for servicing the under-hood components.

The tilt-up hood provides easy access from the ground to:

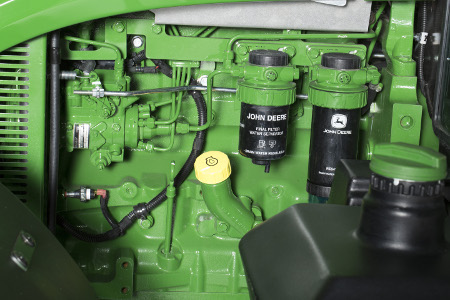

Fuel filters

Fuel filters

Vertical engine oil and fuel filters minimise spilling for cleaner and faster changes. 500-hour service intervals (when using John Deere Torq-Gard™ oil or Plus-50™ lubricant and filter) for engine oil and filter, fuel filter, and cab air filter reduce maintenance costs over the life of the tractor.

Two engine fuel filters provide the needed protection for the fuel system:

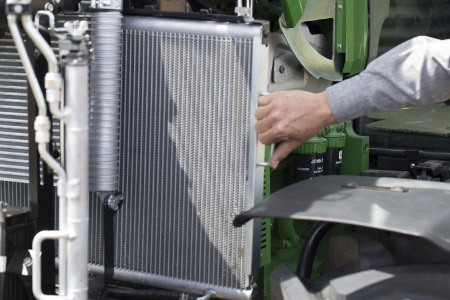

Radiator cleanout

Radiator cleanout

Blowing out the radiator is easy and convenient with the 6E Series Tractors equipped with an in-base, sliding radiator assembly. Open the hood to clean out the radiator, fan, and cooling package. The condenser can be pulled out to one side for better access.

The coolant recovery tank, located behind the air filter, is easily accessible from the ground.

The engine air filter is located under the front of the hood above the radiator. Undoing the quick-attach fastener allows for fast and easy servicing - no tools required. The Power Core air filter removes more than 93 percent of foreign material before it reaches the filter element.

Cab air filter

Cab air filter

The cab air quality system is comprised of two fresh air cab filters. A filter is located on the bottom side of the left- and right- side cab roof is easily accessible by removing two wing screws and a sealed cover plate.

12-V battery (cover off)

12-V battery (cover off)

12-V battery (cover on)

12-V battery (cover on)

Open the hood to access the battery. No tools are needed.

Sight gauge

Sight gauge

Instead of using a dipstick, the transmission/hydraulic oil level is checked with a sight glass on the left side of the rear axle housing on 6E Series Tractors.

Hydraulic oil filter (behind 3-point hitch)

Hydraulic oil filter (behind 3-point hitch)

Transmission/hydraulic oil filter is conveniently located and designed to save the operator service time and reduce maintenance costs.

Change intervals:

![Windshield washer tank (right of selective control valves [SCVs])](https://salesmanual.deere.com/customer/sales/salesmanual/images/AU/en/tractors/features_attachment/6e/windshield_washer.jpg) Windshield washer tank (right of selective control valves [SCVs])

Windshield washer tank (right of selective control valves [SCVs])

The windshield washer tank is conveniently located at the right rear of the cab for easy refilling. This is the same washer fluid tank for the rear window wiper when ordered as a field-installed kit.

Brake pedal adjustment (left shown)

Brake pedal adjustment (left shown)

Easy brake pedal travel adjustment is provided on cab and open operator station (OOS) tractors. Turnbuckle linkage is located at the top side of left and right rear axles.