Are Worn Nozzles Costing You?

Spray nozzles are some of the smallest and most overlooked pieces of equipment on a sprayer, but they have the greatest effect on accuracy, efficiency, and drift potential. Worn spray nozzles can increase application rates and/or change distribution patterns causing under- and over-application impacting your bottom line.

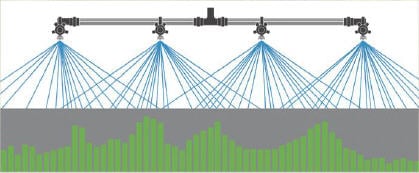

Worn Nozzle Spray Pattern

Under Application

- Reduced yield

- Inadequate weed, pest, or disease control

- Repeated trips over the field

Over Application

- Increased input costs

- Crop damage

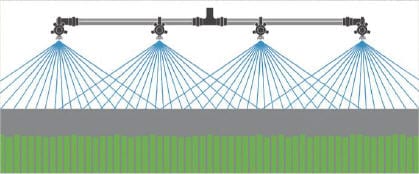

New Nozzle Spray Pattern

Upgrade your R4030, R4038 or R4045 Sprayer with ExactApply™

Make every drop count with an ExactApply Performance Upgrade Kit. Featuring individual nozzle control for precise droplet sizing and consistent application management, ExactApply also provides three times the pulsing frequency of competitive systems along with an industry-exclusive A-B nozzle design.

Is There Buildup in Your Boom?

New herbicides and formulations, tank mix partners with glyphosate … mixing chemicals can lead to buildup in your boom, cross contamination and even yield loss. John Deere offers solutions to help you keep a clean boom including Express End Caps and a complete Express Boom Assembly.

Express End Cap

Trapped air in the boom causes shutoff lag which leads to overspray and residue buildup that can cause cross contamination. With the Express End Cap, air escapes through the last nozzle body eliminating the ‘dead space.’ This provides quicker shutoff, and the cap offers a handy cleanout port for flushing.

Express Boom Assembly

Replace warped poly booms with durable stainless steel and change nozzle spacing as desired to maximise your sprayer performance for years to come. Customise whole boom sections easily – and economically – on select sprayer models.

Direct Injection

Accurately inject chemicals into the carrier flow without having to mix them in the solution tank. No more rinsing the tank between chemicals either.