Never lose sight of the forest.

TimberManager is the business owner’s view to the work site.

Machine documentation in TimberManager

TimberManager Report

Are you interested in profitability?

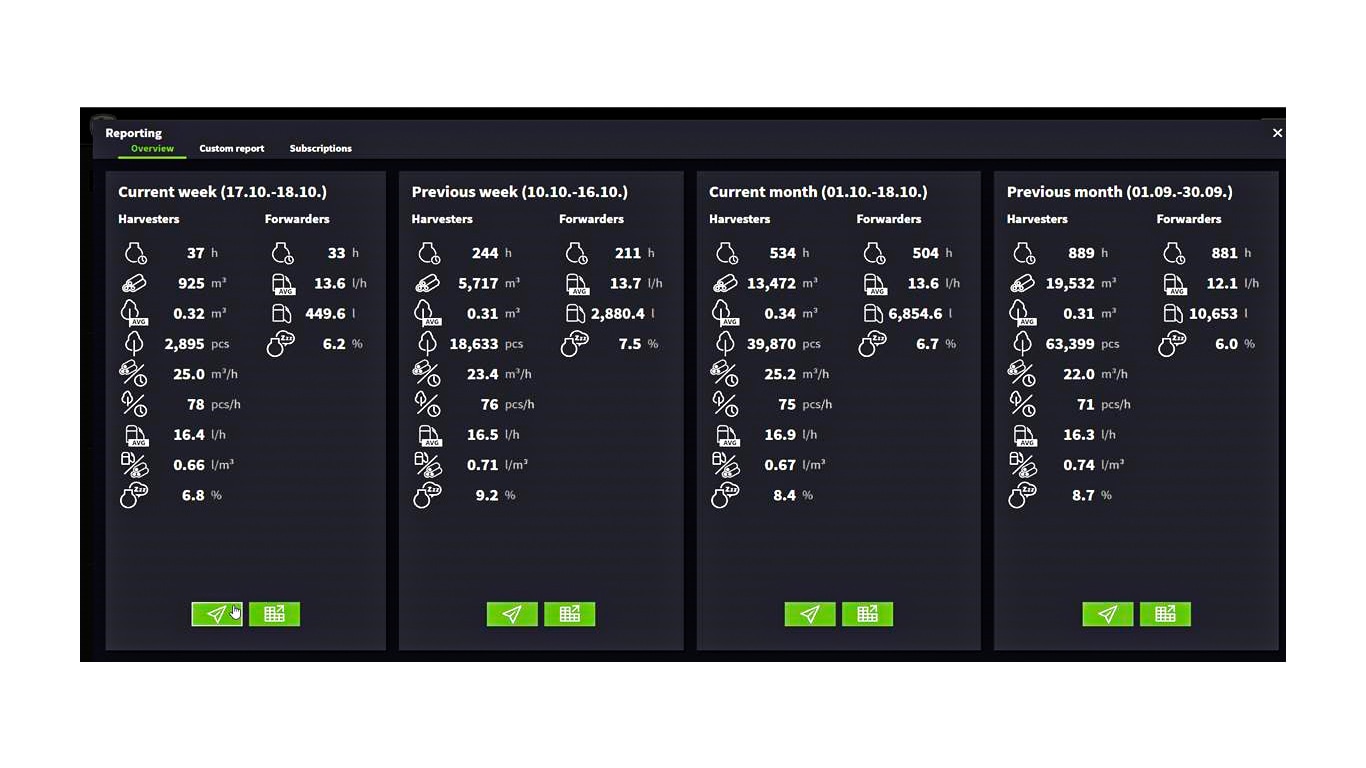

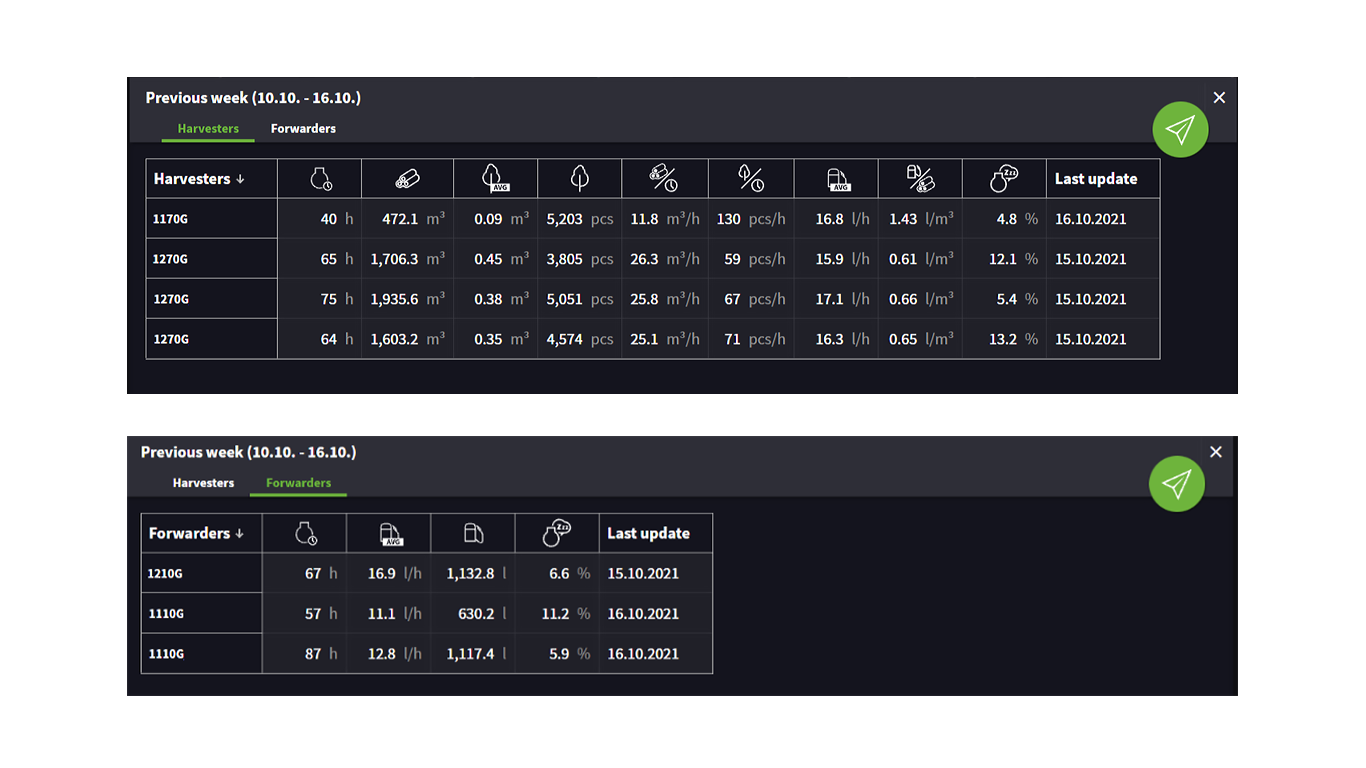

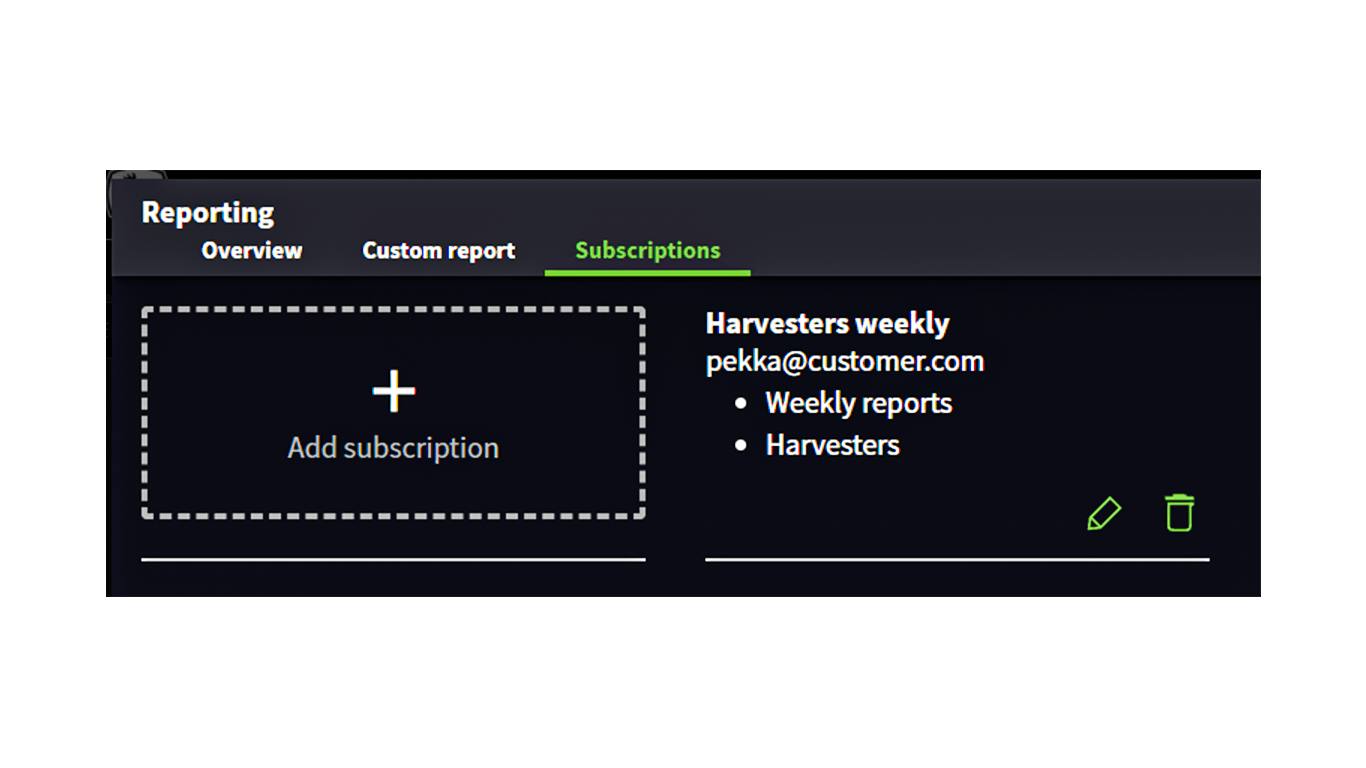

From the TimberManager report you will see essential information about the operation of your forwarders and wheeled harvesters. The report tells you exactly how productive your machines are. With the help of this information you can make the decisions that your business needs.

TimberManager report key metrics

- operating hours

- cubic meters total

- average stem size

- stems total

- cubic meters per hour

- stems per hour

- average fuel consumption litres per hour

- fuel consumption litres per cubic meter

- total fuel consumption (forwarders)

- engine idle time

Starting the work site

When the work site has been started and the landing areas created, the contractor has a real-time view to the progress of all the active work sites.

Progress of the work site

The contractor has real-time information about the progress and an estimate of the completion of the work. It is easy to keep direct contact to work site through the message board.

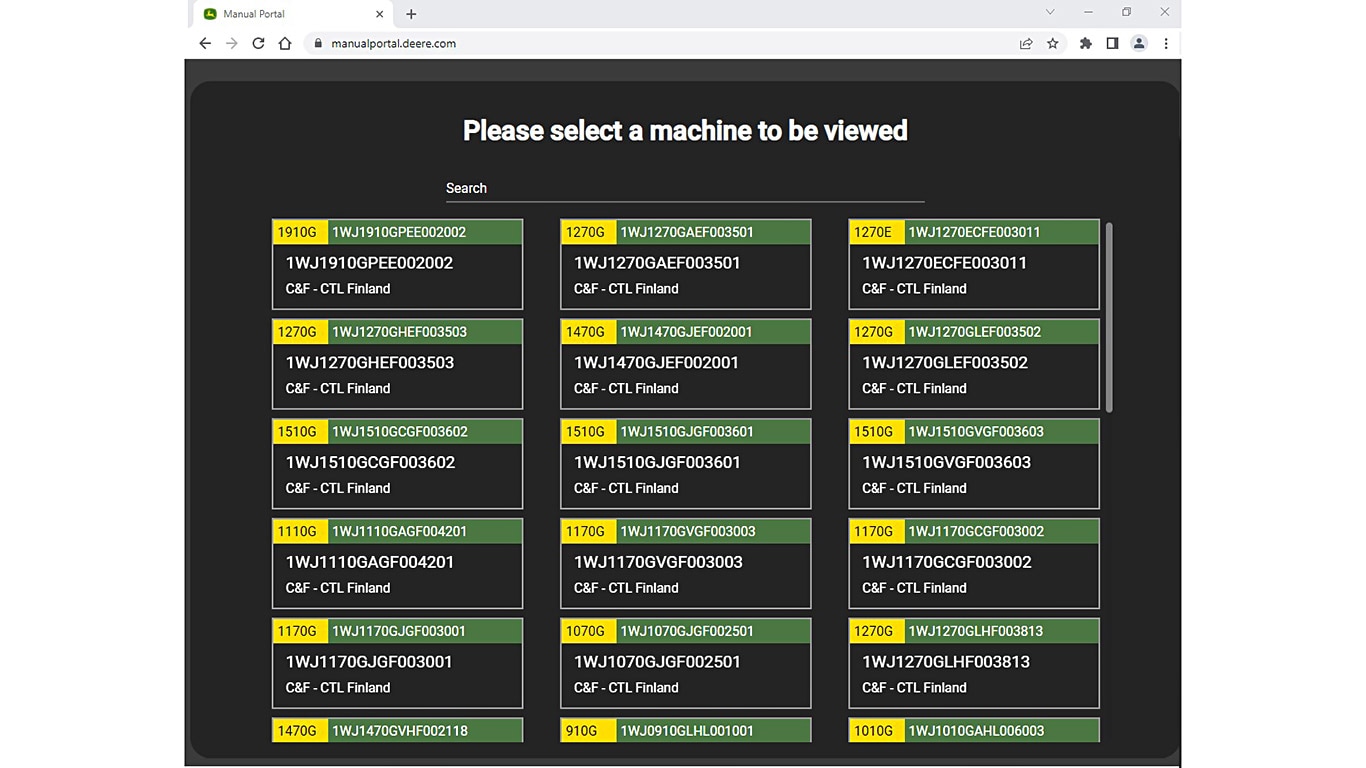

The system first gives a list of the active forwarders and wheeled harvesters and from there, you can browse to the detailed instructions of the individual machine. Harvesters also include the factory-installed harvester head's documentation.

Language can be chosen directly in the user interface and all the supported language versions are available.

Always the latest versions

All the wheeled harvester and forwarder documentation - instruction manuals, schematics and other support material - can now be found on a computer or a tablet, in addition to the machine. There is a link to the documentation in TimberManager's main menu or you can log in directly on manualportal.deere.com. You need a MyJohnDeere user ID to be able to log in.

The system is very simple to use. You can quickly find answers to for example questions about daily maintenance from the machine-specific documentation.

The system is free of charge for all customers with a MyJohnDeere organization and active machines in it. And the web-based system is always up to date.

TimberMatic Maps gives operators a real-time production view to the logging site. The data collected by the harvester’s sensors and the precise GPS-based location of the felled timber, is automatically transmitted from the harvester to the TimberMatic Maps application for use by the forwarder operator. The data between the machines are updated through a cloud service, and all the operators working at the same work site can see all the tree species and assortments with the driving routes right down to the individual logs.