Sustainable forestry solutions

At John Deere, we are committed to providing innovative solutions for sustainable forestry and forest machine manufacturing. Advanced operator-assisting tools are designed to simplify tasks while prioritizing environmental awareness, helping to minimize impact on the forest floor and trees. Our forest machine factory is dedicated to reducing greenhouse gas emissions, minimizing waste, and maximizing recycling. We constantly develop and introduce new technologies that enable a smaller environmental footprint and more efficient operations.

Sustainable forestry solutions

Reducing CO2 emissions

The majority of a forest machine's CO2 emissions occur during its use. To address this, we have focused on reducing fuel consumption to lower the machine’s carbon footprint. Our efforts have led to a fuel consumption reduction of over 20% per cubic meter produced from the E Series to the H Series harvesters. Furthermore, since 2024, our engines have been certified to use renewable diesel, cutting CO2 emissions by up to 90%.

Preserving biodiversity

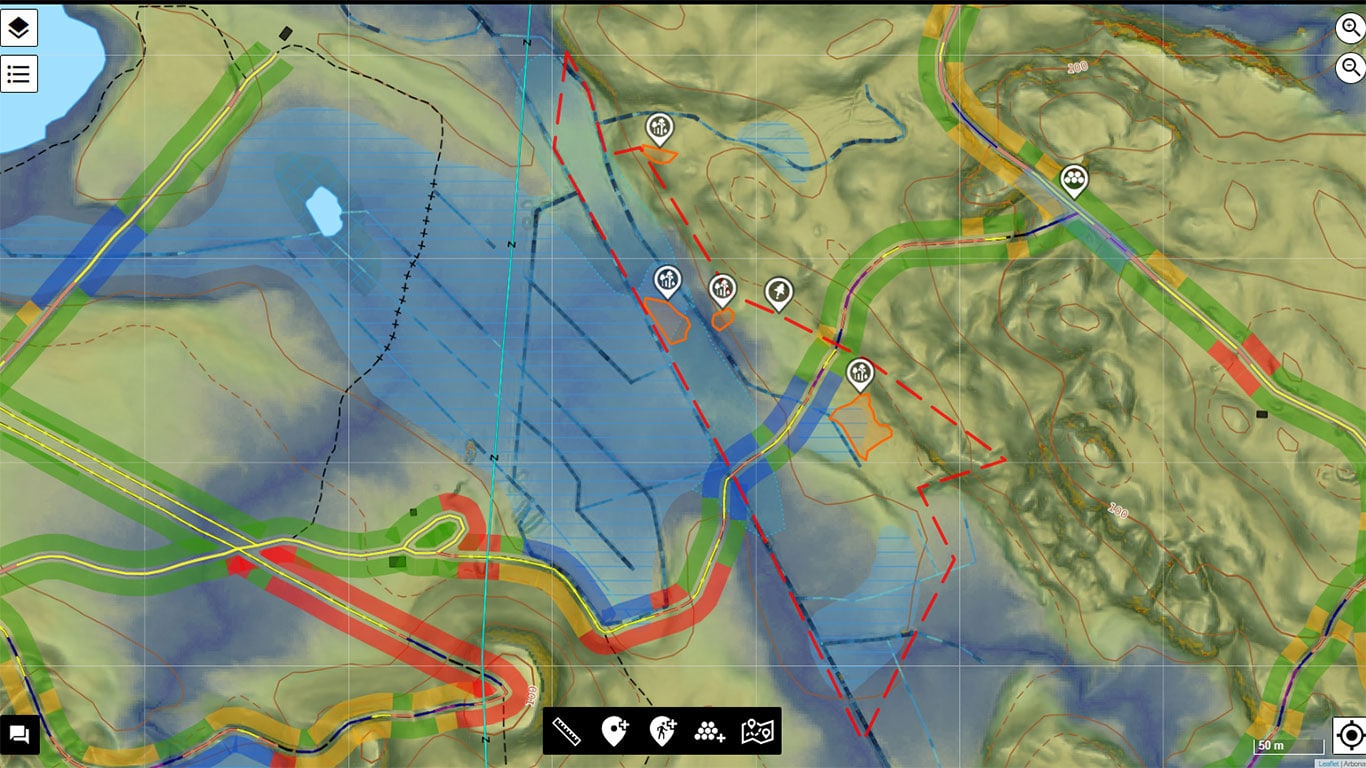

We understand the crucial role of forest machine operators in preserving natural habitats. To support them in their important work, we've developed innovative features like IBC and IHC. Our operator-assisting tools not only simplify tasks but also prioritize environmental awareness. By providing operators with more time to observe the forest environment, they can carry out logging tasks in the most nature-friendly way possible. Our cutting-edge TimberMatic Maps software provides real-time data for precise planning, minimizing impact on the forest floor and trees.

Maximizing machine lifecycle

We prioritize the longevity and performance of our forest machines by using high-quality materials and components. Our service agreements help ensure your machine remains in peak condition, minimizing the need for spare parts and reducing the risk of unexpected repairs. Our comprehensive warranties and service agreements underscore the value of an extended machine lifecycle.

John Deere Reman parts, which include motors and hydraulic components, are remanufactured to reduce the use of new raw materials.

Sustainable manufacturing

Reducing waste and maximizing recycling

Our forest machine factory in Joensuu, Finland is dedicated to reducing waste at every stage of production. From 2012 to 2023, we have decreased waste per ton produced by an impressive 16%. Committed to achieving zero waste to landfill, we ensure that all waste materials are recycled. We continually strive to improve the recyclability rate of waste generated during production and are actively developing new methods to reduce packaging material waste.

Reducing greenhouse gas emissions

We're leading the way in reducing our carbon footprint. Our forest machines in Joensuu are manufactured using renewable energy. In addition, we have introduced solar panels and solar thermal collectors at our Tampere and Joensuu facilities to enhance our eco-friendly practices. From 2012 to 2023, we have reduced energy consumption per ton produced by an impressive 27%. Since adopting the GHG protocol in 2017, we have achieved a remarkable 79% reduction in greenhouse gas emissions. Additionally, we use only renewable diesel in our production, further decreasing our greenhouse gas emissions.

Choosing the right raw materials

We are undertaking several projects to reduce indirect emissions from production. One key initiative is to increase the use of fossil-free steel. Other projects focus on integrating circular economy principles into forest machine manufacturing. We aim to select materials and components that have a smaller carbon footprint and are produced through sustainable processes. Our recyclability target is set at 95%, ensuring that a significant portion of materials can be recycled into new raw materials when the forest machine reaches the end of its lifecycle.

Committed to Quality of Life. John Deere Sustainability Targets for 2030.

Reduce environmental footprint

- 50% less operational CO₂-eq emissions

- 30% less upstream and downstream CO₂-eq emissions

- 15% less waste intensity

Improve product circularity

- Achieve 95% recyclable product content

- Ensure 65% of product content is sustainable material

- Grow 50% in remanufacturing revenue

Sustainability at John Deere

Meaningful Impact. Occurring Daily.

Our customers’ work spans the globe. So, ours does, too. Whether we’re helping farmers put food on tables or construction crews build the roads that connect us, John Deere is working for every person on the planet, even as we work for the planet itself.